Ensuring that your digital prints, screenprints or litho prints are the right colour.

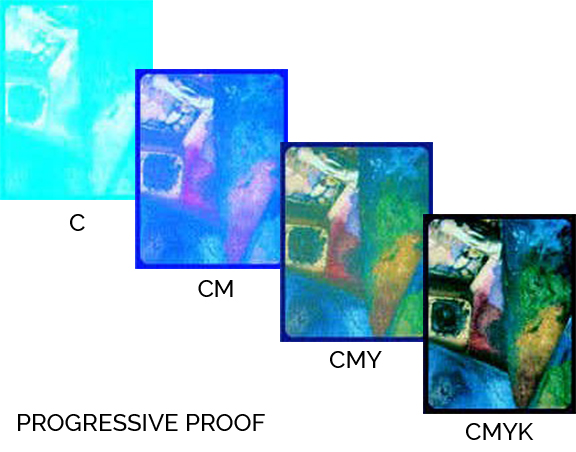

Colour management (CM) for screenprint, flexo, litho & inkjet prepress - in CM all colours are referenced to a theoretical model (Lab). In this way, the RGB of a monitor can be converted to the CMYK of a printer with minimum error.

This is done via ICC profiles, text files aka Look-Up Tables (LUTs), which contain a database of CMYK and RGB values relating to the LAB colour that they produce.

If you have a colour in your DTP programme, the CM module converts to RGB values for the monitor and to CMYK for the printer.

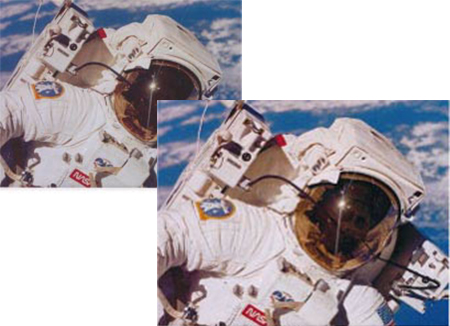

In this way you can 'soft-proof' the job on your monitor, produce a digital proof on your printer and have confidence that the finished job will look as expected.